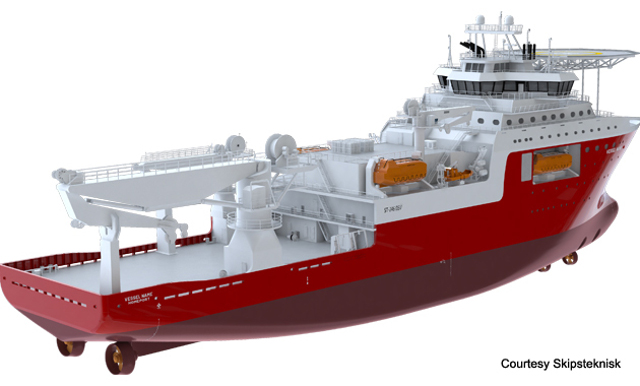

Rolls-Royce has signed on the 29th of November a contract with Huangpu Wenchong Shipyard in China for a package of advanced ship equipment for a new 124 meter long Dive Support Vessel (DSV).

The vessel will be designed by Skipsteknisk in Norway, and is to be delivered in 2017 to its owner, Singapore based Jumeira Offshore Pte. Ltd. It will be equipped with the latest control system for dynamic positioning (DP3) as well as four of the latest Bergen B33:45 generating sets. The total delivery also includes main propulsion, tunnel thrusters and remote controls.

Helge Gjerde, Rolls-Royce, President Commercial – Marine, said: “We are delighted to win this contract in the current difficult market. We are also pleased to welcome Jumeria Offshore as a new customer and we are looking forward to working with them on such an exciting and advanced ship project.”

The vessel’s main engines will be the latest medium-speed Bergen B33:45 from Rolls-Royce launched last year. This engine offers a 20 per cent increase in power per cylinder compared to existing engines in the Bergen range. The engines are very economical and comply with IMO Tier II and III rules. The Bergen B33:45 is designed to run for 25,000 hours between major maintenance when operating at average loads.

The vessel will also be fitted with the Rolls-Royce Icon DP3 (Dynamic Positioning System), this is the first Rolls-Royce contract for DP3 for a vessel built in China.

Dynamic positioning (DP) control systems use several data sources including satellite technology to automatically control a vessel’s thrusters and hold it in exact position where anchoring is not possible. DP systems with classification 3 allow for safe and efficient operations in demanding conditions where any loss of position has the potential to result in fatal accidents, severe pollution or damage with major economic consequences.

Rolls-Royce delivers a DP3 system with an award-winning ergonomic design. A unified look and feel to bridge controls ensures safe operation. The control system itself is closely connected with other inboard control systems and easy to integrate into a bridge arrangement. Among the many advantages is that it provides the vessel owner with a system that is easier and faster to install and commission. Fewer service engineers will also be required for service and maintenance of thrusters and controls later in the vessel’s lifetime.